Menu

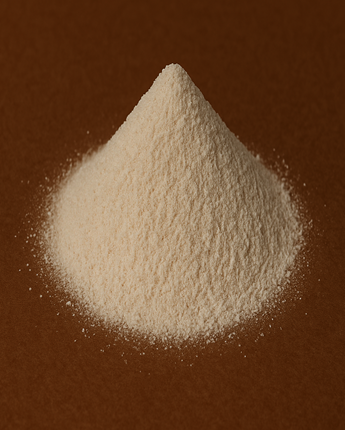

Silica Ramming Mass

Premium Silica Ramming Mass designed for superior furnace lining, thermal stability, and enhanced lining life.

Balkrishna Minerals

Furnace-Grade Silica Ramming Mass for High-Temperature Performance

Our Silica Ramming Mass is manufactured from high-purity quartzite, ensuring optimal lining performance in induction furnaces. Its controlled particle size distribution, low impurity levels, and excellent thermal shock resistance contribute to longer furnace life and reduced power consumption. Silica Ramming Mass is a premium refractory material designed to withstand extreme thermal shocks inside induction furnaces. Its tightly controlled grain size distribution ensures excellent lining density, which leads to better furnace life and reduced power consumption. The mass adapts to furnace shape during ramming, forming a durable monolithic layer with exceptional sintering strength. Its high purity eliminates contamination in molten steel, making it especially important for quality-oriented metal casting setups. Silica ramming mass offers uniform thermal conductivity, helping maintain stable furnace temperatures during continuous operations. Long service life and reduced maintenance make it a cost-effective solution for steel manufacturers.

Specifications:

- SiO₂ Purity: 99.75%+

- Thermal Stability: Excellent at high temperatures

- Refractoriness: 1700°C+

- Magnetite/Alumina added on request

- Grain Size: 0–6 mm (balanced mix)

Engineered to Deliver Trusted Furnace Performance

High thermal shock resistance

Improves furnace lining life

Reduces melting power consumption

Excellent bonding and consistency